Unlocking the Potential of Phase Change Materials for Enhanced Air Cooling and Heating

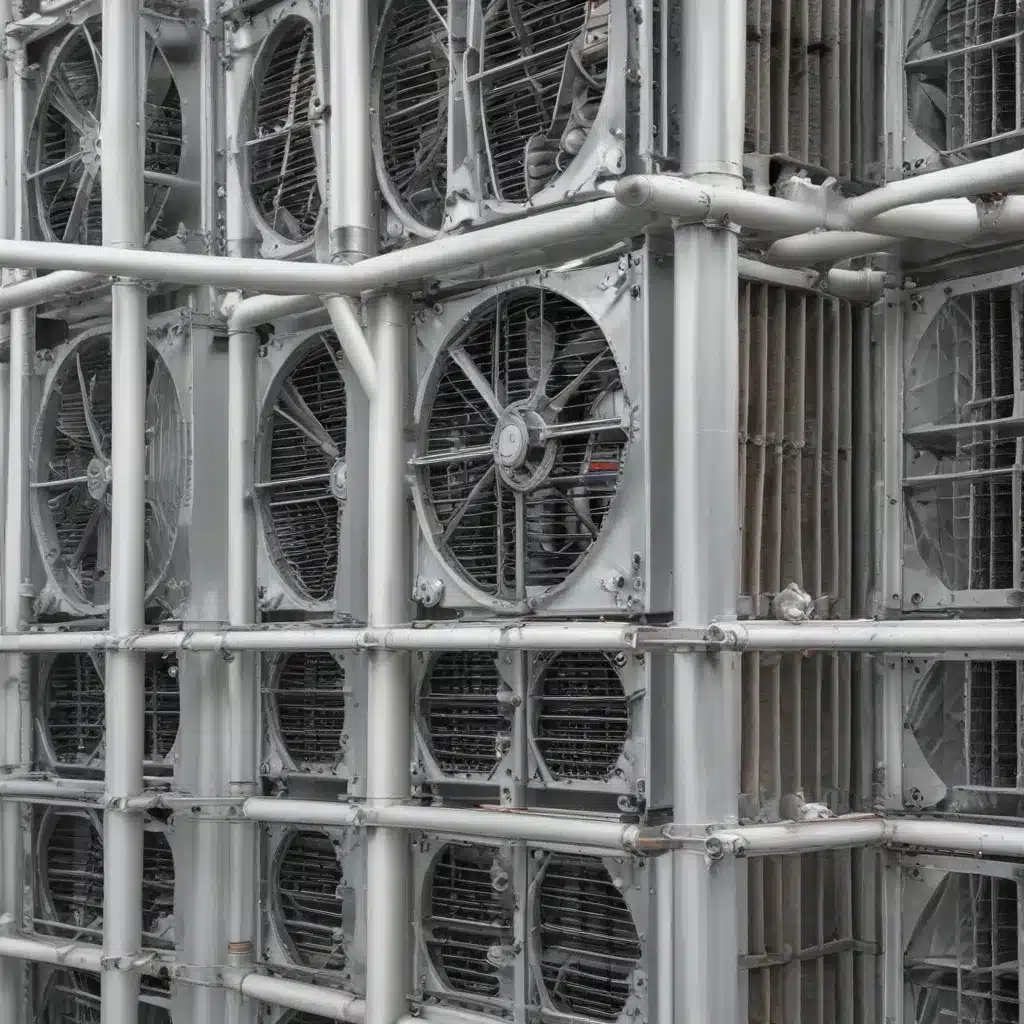

Air-cooled heat exchangers are widely used across various industries, from HVAC systems to industrial processes, due to their versatility, cost-effectiveness, and straightforward maintenance. However, improving the efficiency of these heat exchangers remains a constant challenge for engineers and technicians. One promising solution lies in the integration of phase change materials (PCMs), which can significantly enhance the cooling and heating capabilities of air-cooled systems.

Understanding the Impact of Phase Change Materials

Phase change materials are substances that undergo a phase transition, typically from solid to liquid or liquid to solid, at a specific temperature range. During this phase change, PCMs can absorb or release large amounts of latent heat, making them highly effective for thermal energy storage and management applications.

In the context of air-cooled heat exchangers, PCMs can be strategically integrated to:

-

Enhance Cooling Capacity: During the hot summer months, PCMs can be used to pre-cool the incoming air before it reaches the heat exchanger’s coils. As the hot air passes through the PCM-based heat exchanger, the PCM absorbs the heat, effectively reducing the load on the air conditioning unit and improving its overall efficiency.

-

Improve Heating Performance: Conversely, in the colder winter months, PCMs can be used to pre-heat the incoming air before it reaches the heat exchanger’s coils. As the cold air passes through the PCM-based heat exchanger, the PCM releases its stored thermal energy, warming the air and enhancing the heating capacity of the system.

-

Optimize Energy Consumption: By utilizing the latent heat storage capability of PCMs, air-cooled heat exchanger systems can reduce their energy consumption during peak demand periods, leading to significant cost savings and environmental benefits.

Dual-PCM Systems for Year-Round Efficiency

While single-PCM systems can be highly effective for either cooling or heating applications, the introduction of dual-PCM systems takes this concept a step further. These advanced systems integrate two distinct PCMs with different melting temperatures, tailored to the specific climatic conditions of the installation site.

For example, during the summer, a high-melting-point PCM can be used to absorb heat from the incoming air, while in the winter, a low-melting-point PCM can be employed to release heat and warm the air. This strategic dual-PCM approach ensures optimal performance and energy efficiency throughout the year, without the need for system modifications.

Enhancing Heat Transfer with Nanomaterials

One key factor in improving the efficiency of PCM-integrated air-cooled heat exchangers is enhancing the heat transfer between the PCM and the surrounding air. This is where the integration of nanomaterials comes into play.

Nanomaterials, such as graphene, carbon nanotubes, and metal oxide nanoparticles, can be dispersed within the PCM to create nano-enhanced PCMs (nePCMs). These nePCMs exhibit superior thermal conductivity compared to their traditional PCM counterparts, enabling faster heat absorption and release during the phase change process.

By incorporating nePCMs into air-cooled heat exchanger designs, engineers can achieve:

- Improved Charging and Discharging Rates: The enhanced thermal conductivity of nePCMs allows for faster heat transfer, leading to reduced charging and discharging times for the PCM system.

- Increased Heat Transfer Coefficients: The presence of nanomaterials in the PCM can significantly enhance the convective heat transfer coefficients between the air and the PCM, further improving the overall system efficiency.

- Expanded Operating Temperature Ranges: The tailored phase change temperatures of nePCMs can be engineered to match the specific climatic conditions of the installation site, ensuring optimal performance throughout the year.

Optimizing Air-Cooled Heat Exchanger Design

Beyond the integration of PCMs and nanomaterials, the design of the air-cooled heat exchanger itself plays a crucial role in maximizing efficiency. Factors such as the arrangement and geometry of the PCM containers, the airflow patterns, and the overall heat exchanger configuration can all impact the system’s performance.

Researchers have explored various PCM container layouts, including inline and staggered cylinder arrangements, to understand their influence on heat transfer characteristics, air velocity distributions, and overall system efficiency. By carefully optimizing the heat exchanger design, engineers can unlock the full potential of PCM-integrated air-cooled systems.

Practical Maintenance and Troubleshooting

Maintaining the optimal performance of PCM-integrated air-cooled heat exchangers requires a proactive approach to maintenance and troubleshooting. Regular inspections, cleaning, and monitoring of the PCM’s physical and thermal properties are essential to ensure the system continues to operate at peak efficiency.

Technicians should be vigilant for any signs of PCM degradation, such as changes in melting/solidification temperatures, reduced latent heat storage capacity, or the accumulation of impurities. Prompt identification and resolution of these issues can help extend the system’s lifespan and maintain its energy-saving benefits.

Furthermore, integrating advanced monitoring and control systems can provide valuable insights into the heat exchanger’s performance, enabling data-driven decision-making and proactive maintenance strategies.

Unlocking the Full Potential of PCM-Integrated Air-Cooled Heat Exchangers

The integration of phase change materials, combined with the strategic use of nanomaterials and optimized heat exchanger design, holds immense potential for transforming the efficiency of air-cooled heat exchanger systems. By harnessing the unique thermal properties of PCMs and nePCMs, engineers and technicians can unlock significant energy savings, reduced operating costs, and enhanced system performance in a wide range of industrial and commercial applications.

As the demand for sustainable and energy-efficient HVAC solutions continues to grow, the adoption of PCM-integrated air-cooled heat exchangers will undoubtedly play a crucial role in shaping the future of thermal management technology. By staying at the forefront of these advancements, professionals in the air-cooled heat exchanger industry can position themselves as leaders in delivering innovative, cost-effective, and environmentally responsible solutions to their clients.

To learn more about the latest advancements in PCM-integrated air-cooled heat exchangers, explore the resources available on https://www.aircooledheatexchangers.net/. Our experts are dedicated to providing industry-leading insights and practical guidance to help you optimize the performance and efficiency of your air-cooled heat exchanger systems.