Introduction: The Importance of Air-Cooled Heat Exchanger Design and Performance

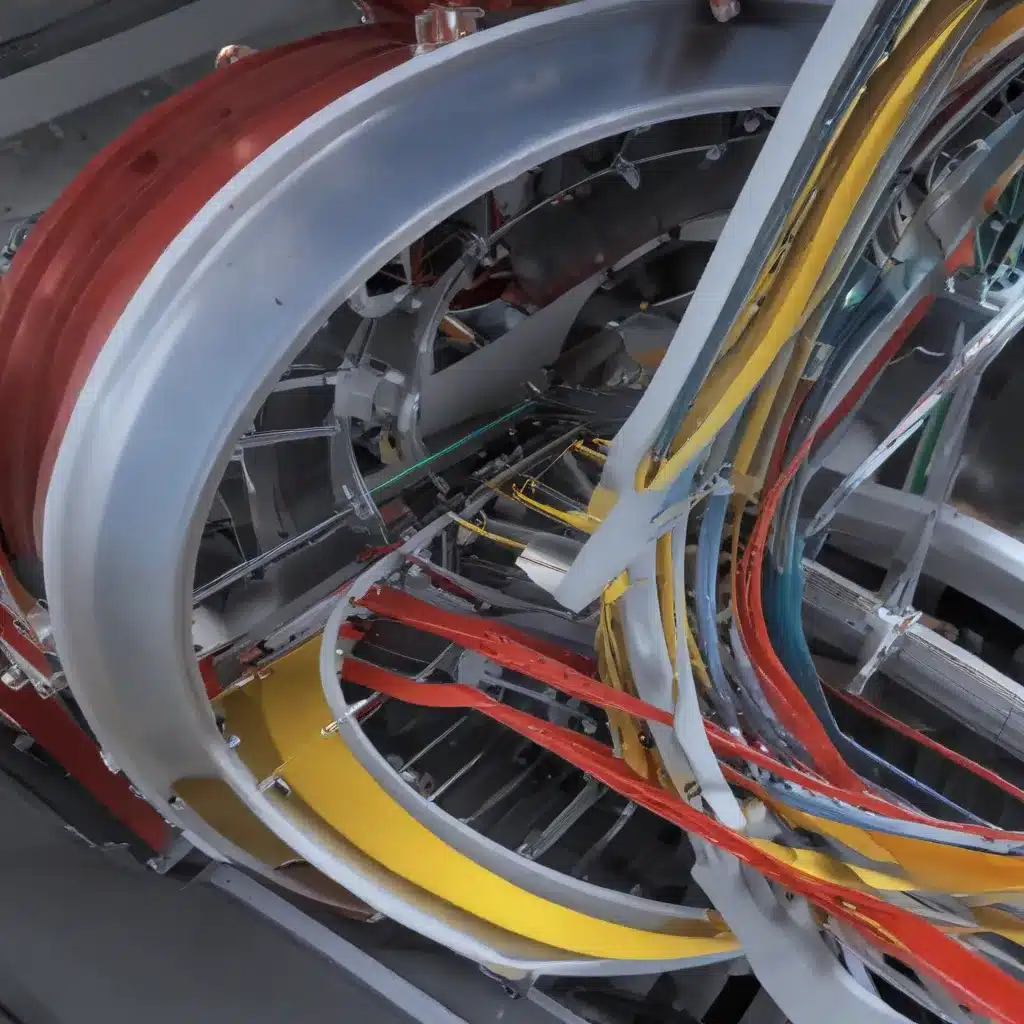

Air-cooled heat exchangers play a vital role in a wide range of industries, from power generation and manufacturing to HVAC systems and industrial processes. Their efficient heat transfer capabilities, low maintenance requirements, and environmentally friendly nature make them an increasingly popular choice for various applications. However, optimizing the design and performance of these critical components requires a deep understanding of the complex multi-physics phenomena involved.

In this comprehensive article, we will delve into the state-of-the-art research on multi-physics coupled acoustic-mechanics analysis and synergetic optimization techniques for air-cooled heat exchangers. We will explore how the integration of computational fluid dynamics (CFD), structural mechanics, and aeroacoustics can lead to significant improvements in heat transfer, noise reduction, and overall system efficiency.

Leveraging Multi-Physics Coupled Modeling for Optimal Design

Air-cooled heat exchangers are subject to a complex interplay of fluid dynamics, structural vibrations, and acoustic phenomena. Accurately predicting and optimizing their performance requires a holistic approach that considers these multi-physics couplings.

Fluid-Structure Interaction (FSI) Analysis

The airflow and heat transfer within an air-cooled heat exchanger are intimately coupled with the structural dynamics of the heat exchanger components. Vibrations can lead to changes in the flow patterns, heat transfer coefficients, and even material fatigue. By incorporating fluid-structure interaction (FSI) analysis, engineers can gain a deeper understanding of these complex interactions and optimize the design for improved reliability and performance.

Computational Aeroacoustics (CAA)

The high-velocity airflow through air-cooled heat exchangers can generate significant noise, which can be detrimental to the surrounding environment and personnel. Computational aeroacoustics (CAA) techniques, such as the Ffowcs Williams-Hawkings (FW-H) model, enable the prediction of the acoustic characteristics of the heat exchanger, allowing for the development of noise-reducing design strategies.

Multi-Objective Optimization Techniques

Optimizing air-cooled heat exchangers often involves balancing multiple, sometimes conflicting, objectives, such as maximizing heat transfer, minimizing pressure drop, and reducing noise emissions. Advanced multi-objective optimization algorithms, such as genetic algorithms and neural networks, can be leveraged to explore the design space and identify the optimal trade-offs between these competing goals.

Case Study: Optimizing a Twin-Fluid Atomization Nozzle

To illustrate the power of the multi-physics coupled acoustic-mechanics approach, let’s consider the optimization of a twin-fluid atomization nozzle, which is a critical component in various industrial applications, including wet dust removal systems.

Multi-Physics Coupled Modeling

The atomization process within the twin-fluid nozzle involves a complex interplay of fluid dynamics, structural vibrations, and acoustic phenomena. By employing a multi-physics coupled approach, incorporating CFD, structural mechanics, and CAA models, researchers were able to accurately simulate the behavior of the nozzle under various operating conditions.

The discrete phase model (DPM) and large eddy simulation (LES) were used to capture the intricate flow patterns and droplet formation within the nozzle, while the Ffowcs Williams-Hawkings (FW-H) model enabled the prediction of the acoustic characteristics.

Optimization Methodology

To optimize the twin-fluid nozzle, the researchers leveraged a multi-objective synergetic optimization algorithm, combining the strengths of orthogonal test matrix analysis, a backpropagation (BP) neural network, and a genetic algorithm.

The orthogonal test matrix analysis was used to establish an initial database, identifying the key parameters and their relative influence on the nozzle’s performance, including droplet size, effective atomization range, and sound pressure level (SPL).

The BP neural network was then trained on this database, learning the complex nonlinear relationships between the design parameters and the performance metrics. Finally, the genetic algorithm was employed to explore the design space and converge on the optimal parameter values, striking a balance between the competing objectives.

Optimized Design and Performance Improvements

The optimized twin-fluid nozzle design, achieved through the multi-physics coupled acoustic-mechanics analysis and synergetic optimization, demonstrated remarkable improvements in performance:

- Droplet Size Reduction: The optimized nozzle significantly reduced the droplet size in the atomization flow field, resulting in a more effective capture of fine dust particles.

- Increased Atomization Range: The effective atomization range of the nozzle was enhanced by 71.56%, enabling a broader coverage area for dust removal.

- Noise Reduction: The sound pressure level (SPL) of the nozzle was reduced by an average of 38.96% across the measurement points, creating a quieter working environment.

These substantial improvements in the nozzle’s performance showcase the power of the multi-physics coupled approach and the synergetic optimization techniques in unlocking the full potential of air-cooled heat exchanger and related industrial components.

Optimizing Air-Cooled Heat Exchangers: Key Considerations

The insights gained from the twin-fluid nozzle optimization case study can be applied to the design and improvement of air-cooled heat exchangers. Here are some critical factors to consider when optimizing these crucial systems:

Fluid-Structure Interaction (FSI)

Accurately modeling the complex interplay between the airflow, heat transfer, and structural dynamics is essential for predicting and mitigating issues such as vibration-induced fatigue, flow-induced noise, and heat transfer degradation.

Aeroacoustic Optimization

Reducing the noise emissions from air-cooled heat exchangers is crucial for minimizing the impact on the surrounding environment and personnel. Computational aeroacoustics (CAA) techniques can guide the design of noise-reducing features, such as optimized fan blade geometries and effective sound absorption materials.

Multi-Objective Optimization Strategies

Air-cooled heat exchanger design often involves balancing multiple, sometimes conflicting, objectives, such as maximizing heat transfer, minimizing pressure drop, reducing energy consumption, and ensuring structural integrity. Leveraging advanced optimization algorithms can help identify the optimal trade-offs and guide the design process.

Maintenance and Reliability Considerations

Incorporating maintenance and reliability aspects into the optimization process can lead to air-cooled heat exchanger designs that are not only high-performing but also easy to maintain and less prone to failures. This includes considerations such as accessibility, material selection, and fault-tolerant features.

Conclusion: The Path Forward for Air-Cooled Heat Exchanger Excellence

The integration of multi-physics coupled modeling and synergetic optimization techniques has emerged as a powerful approach for unlocking the true potential of air-cooled heat exchangers. By considering the complex interactions between fluid dynamics, structural mechanics, and acoustics, engineers can design and optimize these critical components to deliver unprecedented levels of performance, efficiency, and reliability.

As the demand for air-cooled heat exchangers continues to grow across various industries, the insights and methodologies presented in this article will serve as a valuable guide for thermal engineers and system designers. By embracing these cutting-edge techniques, the air-cooled heat exchanger community can drive innovation, enhance sustainability, and create a more energy-efficient and environmentally friendly future.

To learn more about the latest advancements in air-cooled heat exchanger technology, visit our website at https://www.aircooledheatexchangers.net/. Our team of experts is dedicated to providing practical tips, in-depth insights, and industry-leading solutions to help you optimize the performance and reliability of your air-cooled heat exchangers.